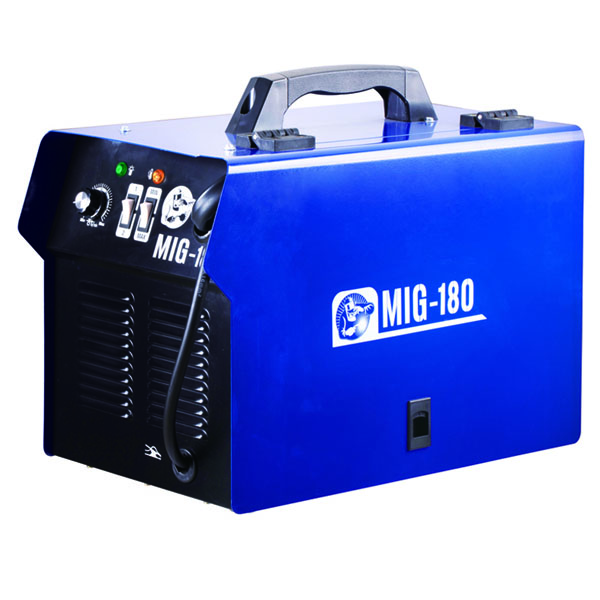

Product Specification of the MIG-200 welder

|

ITEM |

MIG-200 |

|

Power Voltage(V) |

AC 1~230±15% |

|

Rated Input Capacity(KVA) |

6.6 |

|

Efficiency(%) |

85 |

|

Power Factor(cosφ) |

0.93 |

|

No Load Voltage(V) |

56 |

|

Current Range(A) |

30~200 |

|

Duty Cycle(%) |

40 |

|

Welding Wire (Ømm) |

0.8~1.0 |

|

Insulation Degree |

F |

|

Protection Degree |

IP21S |

|

Measurement(mm) |

505X265X285 |

|

Weight(KG) |

N.W.:11 G.W.:14.4 |

Product Feature

1.Single-phase, portable , fan-cooled wire welding machine for flux (no gas) and MIG/MAG(gas) welding .

2.The kit for welding different types materials such as steel , stainless steel.

3.Steel and aluminum is available on request.

Customized Service

(1) Customer's Company Logo

(2) User Manual( Different content or language)

(3) Notice Sticker Design

(4) Ear Sticker Design

MOQ: 100 PCS

Delivery: 30 Days after receive deposit

Payment : 30%TT as deposit, the balance to be paid before shipment .

FAQ

1. Are you trading company or manufacture?

We are manufacture located in Ningbo City,DABU have a strong team with 300 staff ,40 of them are engineers. we have 2 factories, one is mainly in producing Welding Machine, Welding Helmet and Car Battery Charger, Other company is for producing welding cable and plug.

2.Is the sample paid or free?

The sample for weldingmasks and power cables are free of charge, you just need pay for courier cost. You will pay for the electric welding machine and its courier cost.

3. How long can I expect the sample electric welding machine ?

It takes 3-5 days for sample and 4-5 working days by shipping.

4. How long does it take for a bulk order ?

It takes about 35 days

5. Which certificate do you have?

CE,3C,GS...

6. What are your advantages over other manufacturers?

we have whole set machines for producing welding machine We produce the welding machine and helmet shell by our own plastic extruders, painting and decal ourself, Produce the PCB Board by our own chip mounter, assemble and packing. As all the producing process is controlled by ourself, so can make sure steady quality and after-sales service.